The Final Manufacture

Task 11.6 - Final Leather Organizer Build

This is a pattern layout template made for the production of the leather organiser. As will be seen in the final production

images, the patterns were changed slightly to accommodate for better access of the tools.

The pieces of Chromexcel leather were cut from the pattern templates (to the left) and then sewn together using a saddle stitching method. This is where a single thread line has two needles on each end, and they are sewn simultaneously through the same holes going in opposite directions to create a strong double-sided stitch.

The pouches for the tools on the front were measured by adding the width and the thickness of the item. The pouch leather diameter was calculated by:

(width)+2x(thickness)+ 2mm for thread line. I measured all the tools this was, added the values of the leather diameter size and then produced the one piece of leather that would fit to the front of the organizer.

The names of all of the pouches and tools were stamped into the leather then filled with gold paint to highlight each word.

Final Task Booklet Build - Printing and Binding

After printing the booklet out onto waterproof paper, the and trimmed, the centre fold made on each page and then the pages were stacked. The order of the pages and the quality of printing was checked on each page, to make sure there were no page print errors

or smudging.

The front cover was

printed on a vintage

effect waterproof paper. To make the front

cover ridged I used a 140gsm paper stock to strengthen the 70gsm

vintage paper. To make it look like one piece, I folded over the

edges of the Vintage paper onto the correctly trimmed 140gsm paper.

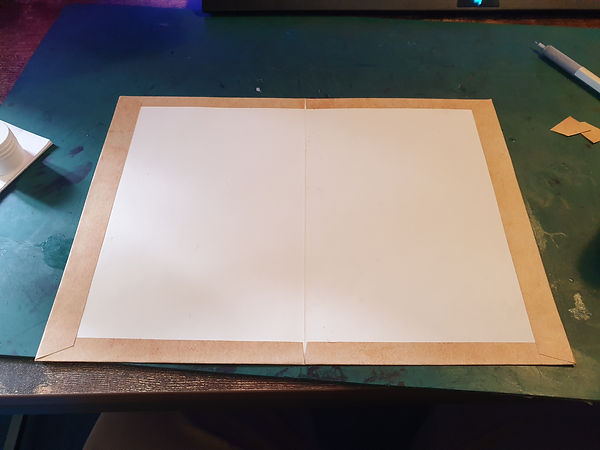

To allow the glue on the front cover to dry

properly and not

wrinkle, I pressed the cover under a block of wood with some weights on it over night. I also kept the content pages folded under the wooden block too, this made the folds much more crisp.

I tested the Folds of the cover over a piece of foam to check that it would allow for the thickness of the

content pages.

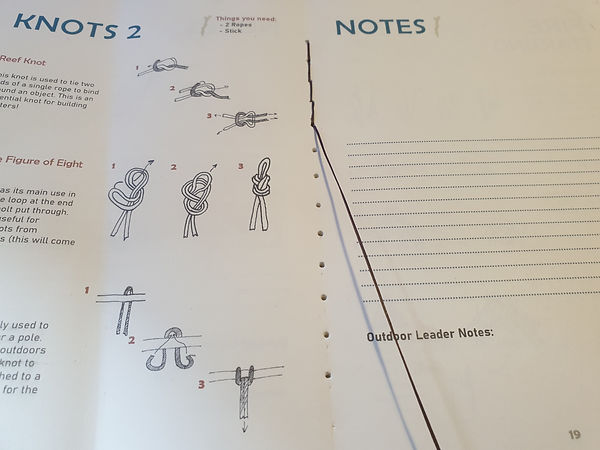

To bind the booklet, I punched 1mm holes 10mm apart down the centre

fold of the booklet. Then using the same

saddle stitch method to sew the leather

together, I bound the the content pages and the cover together.